SYSWARE.EDM

Engineering Data Management System

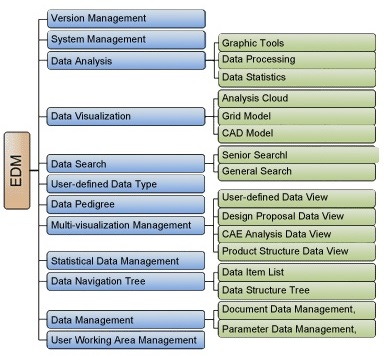

EDM is committed to data management, operation and process that generate these data management in engineering design process, such as design

parameter, design model, analysis model, test data, report, etc.

Main Features of EDM:

Centered by product structure, the current PDM system is a data management system emphasizing on definition, management and maintenance of design

result, which is suitable for data collaboration in stage of detail design, production and maintenance.

Due to the strict internal logic between design process and process data, the product design process is centered by process management and process data

management, which includes design, analysis, performance management,as well as correlation and data history management.

【Structural Relation Management】

EDM manages process data of design parameter, design model, analysis model, report. etc. through information tree. Each branch of information tree is

associated with related document or data. Users can define, edit, view, search and delete the information tree.

【Development Process Management】

Data evolution is essentially a process data management mode similar to process chart, and the design node is displayed in form of data item. Through

the intuitive process map, the source of process data and whereto can beclearly articulated.

【Correlation Management】

Process data correlation management is based on data evolution management, which contains correlation management of product structure tree and

process data, and CAD data and CAE data. User will receive notification when data correlation changed.

【Data Visualization】

Various kinds of process data of CAD data, CAE data, reports, charts, etc. can be viewed through lightweight mode.

【PDM Interface】

According to requirements of PDM model and specifications of product BOM, product definition data in process data management system can be

transferred to PDM system.

版权所有©索为技术股份有限公司 2006-2022 保留一切权利.

版权所有©索为技术股份有限公司 2006-2022 保留一切权利.